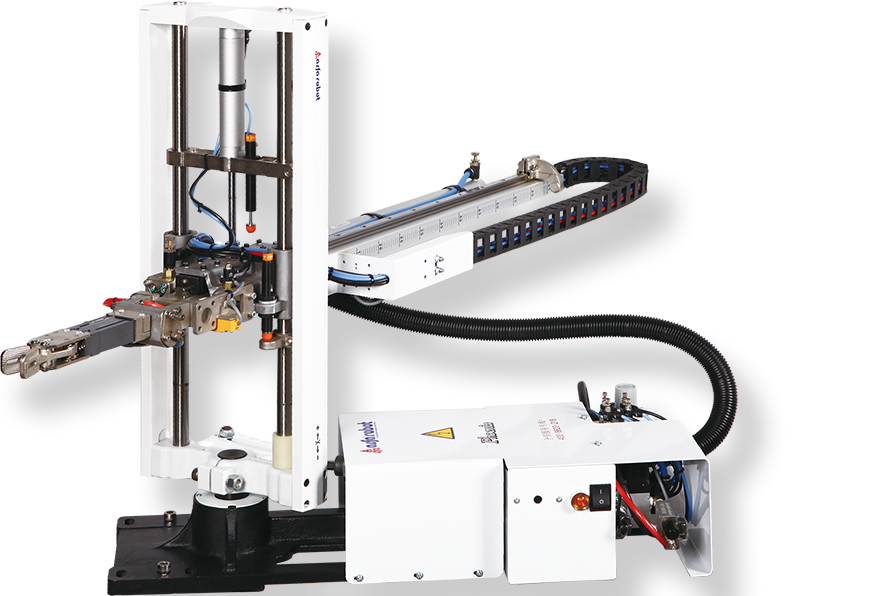

Alfa Robot Phoenix Vertical Series - Picker for Vertical Injection Machine

Phoenix Vertical Series - Picker for Vertical Injection Machine

PV-RTModel: 450/650/850

R: Rotate 60-90°, no mark does not rotate

T: The clamp rotates 180° without a mark and does not rotate.

Standard

- Language switchingSupport Chinese or English or Chinese and Japanese switching

- Teaching functionPrograms can be programmed as needed to achieve special actions

- Spin out standbyUse when the top of the mold interferes with the robot or fixture

- Fixture detectionHigh performance magnetic switch to confirm the presence or absence of gripping the material or product

- Fixed mold removalWhen the product is in the form of a template, it can be set to the fixed mold side to take the product.

- Built-in materialAfter the nozzle is clamped in the mold or the product is sucked, the material or product can be released in the mold.

- Conveyor belt interfaceControl conveyor belt operation, stop

- Memorable programCan save 24 sets of mold data

- Screen saver settingsThe man-machine does not use automatically for more than a certain period of time, and the time can be set.

- Spin-in and double-head valve controlWhen the power is off, the screw-out mechanism remains in the original state and does not interfere with the injection molding machine.

- USB interfaceUse U disk to upload, download mold data, update program

Optional

- Suction loopScalable 1 set suction circuit

Spraying agentWhen the product is not released, the interval can be set and the spray time can be set.

Medium plate inspectionConfirm the position of the middle plate during the three-plate mode to avoid the jib collision

European standard connectorConfigurable EUROMAP12 or EUROMAP67 standard connectors for connection to injection molding machine - Spraying agentWhen the product is not released, the interval can be set and the spray time can be set.

- Medium plate inspectionConfirm the position of the middle plate during the three-plate mode to avoid the jib collision

- European standard connectorConfigurable EUROMAP12 or EUROMAP67 standard connectors for connection to injection molding machine

Robots &

Automation

- Alfa Robot Falcon Series - Side Entry Servo-Driven Robots

- Alfa Robot Explorer Series - PET Preform Beam Robots

- Alfa Robot VA Series - Servo Driven Longitudinal Beam Robots

- Alfa Robot Bomarc Series - Servo Driven Beam Robots

- Alfa Robot Bomarc Economical Series - Servo Driven Beam Robots

- Alfa Robot Phoenix Series - Swing-Arm Robots

- Alfa Robot Phoenix Vertical Series - Picker for Vertical Injection Machine

- Alfa Robot New Titan Series - CNC AC Servo Beam Robots

- Alfa Robot Titan Series - CNC AC Servo Beam Robots

- Alfa Robot Redstone Series Robots for 50T-800T

contact us with

any

questions

Contact Us

Anytime

24/7 Service & Support

Huge Range Of Machinery Available

18 Months Warranty With Everything Sold

All Our Staff Are Service Technicians