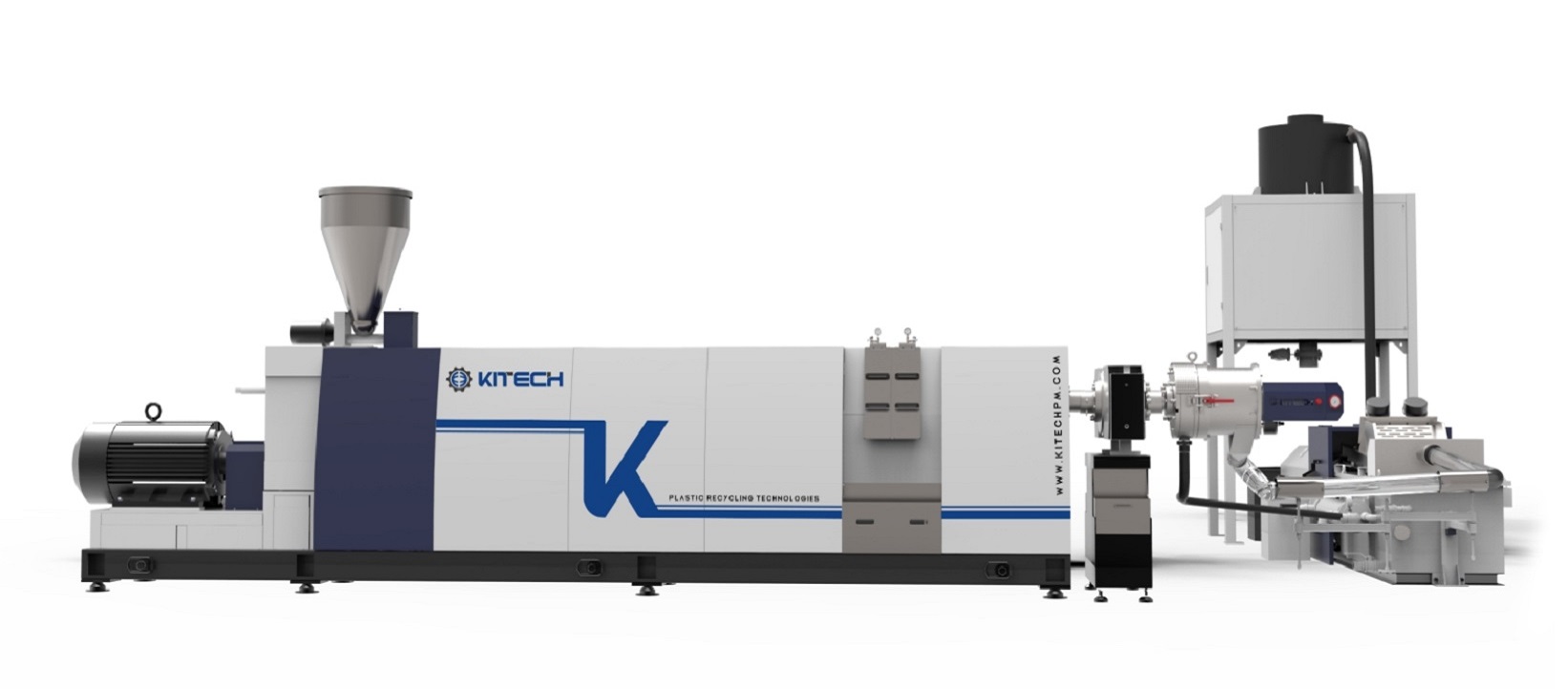

Kitech Rigid Flakes Pelletizing System - KSP

Applicable Materials: HDPE/PP/ABS/PS/PC/PET Rigid Flakes

The KSP series single screw plastic regrind pelletizing system combines quantitative feeding, high efficiency extruder, different type of filter and different types of pelletizer by modular design. It provides best solution for PE, PP, PS, ABS, PC, PET, PA and many other rigid plastic regrind recycling.

Feeding

Dosing feeder with PLC intelligent controller, which ensures the extruder run steadily.

Extrusion

High efficiency barrel and screw used for extruder with excellent plasticizing result and high output capacity. Adopt high wear resistant alloy material to ensure 1.5 times service life of normal one.

Degassing

Force double vacuum degassing system to get rid of the low molecular, moisture and printing ink effe -ctively, make sure high quality output pellets.

Filtration

Plate type, piston type, back flush type and automatic self-cleaning type filter, you have different choice according to impurity contents in material and your habit.

Pelletizing

New European design water ring pelletizer, Cutting speed of pelletizer controlled automatically by PLC according to the pressure of die head, which could achieve the uniform size for output pellets.

Drying

Vibration dryer combined with horizontal type centrifugal dryer to get well dried final granules.

Controlling

Thanks to Siemens PLC and HMI, KCP series recycling pelletizing machine provides high intelligent operation system which is easy to operate and save manpower.

Recycling

Systems

- Wiscon Double Shaft Shredder DS Series

- Wiscon Large Single Shaft Shredder T Series

- Wiscon Crusher CS Series

- Wiscon Large Crusher CL Series

- Wiscon Large Double Shaft Shredder DL Series

- Wiscon Small Single Shaft Shredder P Series

- Kitech Compacting Pelletizing System - KCP

- Kitech Rigid Flakes Pelletizing System - KSP

- Wiscon Shredder-Crusher Combined CT Series

- Wiscon Confidential information destruction and crushing system

- Wiscon PP/PE Daily Miscellaneous Material Washing Line

- Wiscon PET Bottle Recycling System

contact us with

any

questions

Contact Us

Anytime

24/7 Service & Support

Huge Range Of Machinery Available

18 Months Warranty With Everything Sold

All Our Staff Are Service Technicians