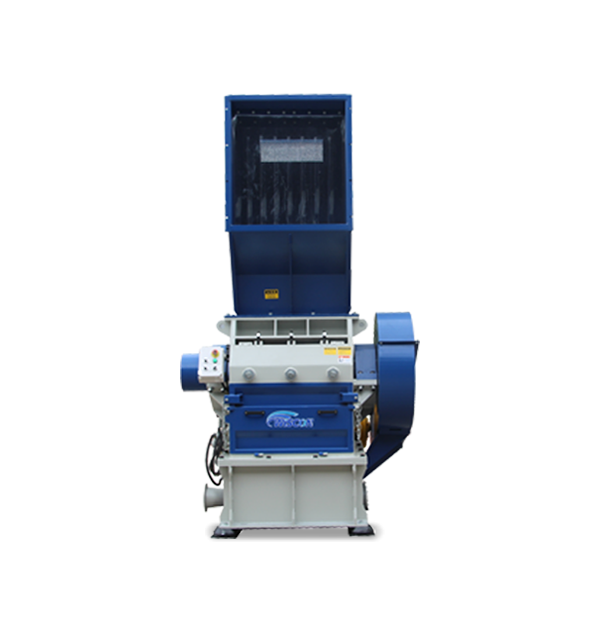

Wiscon Crusher CS Series

Crusher

CS Series

Working Principle

The plastic crusher drives the moving knife cutter head to rotate at high speed through the motor. During the high-speed rotation of the moving knife, it forms a relative movement trend with the fixed knife. The gap formed between the moving knife and the fixed knife creates a plastic crushing and shearing incision. The block of plastic is crushed, and the crushed material is filtered through a screen to filter the particle size and output.

Scope of Application

This crushing economy can be used to crush and recycle waste plastics such as plastic boxes, plastic pipe fittings, blow molding parts, PET bottles, household appliances shells, and daily miscellaneous plastic products. It is usually used as a secondary crushing operation.

Product Introduction

Wiscon plastic crusher manufacturer`s main plastic crusher is especially suitable for crushing plastic products with small size and low hardness. Its plastic crusher price advantage and high output are widely used in the plastic recycling industry.

The plastic crusher should be aimed at plastic blocks, films, pipes, PET bottles, plastic head materials, machine head materials, nozzle materials, leftover materials, etc.

The output range is between 500kg/h-3000kg/h, which is suitable for the solid waste recycling industry and plastic product enterprises scrap processing.

The size of the plastic materials after crushing can be adjusted according to the aperture of the screen. The size is adjusted.

Features

Characteristics of the Equipment

1. The material crusher is easy to operate, easy to change the

knife , and fast.

2. The structure design of the knife holder is optimized. The claw knife can disperse the force, so that the shear force of each knife is increased. It is suitable for crushing thick materials, hard materials, Rubber head, etc., effectively improve the cutting force of the tool and reduce the wear of the tool.

3. It is equipped with an electronic control system design. The hopper adopts a double-layer structure and is filled with soundproof materials, which makes the equipment have good safety and environmental protection, power saving and durability.

Recycling

Systems

- Wiscon Double Shaft Shredder DS Series

- Wiscon Large Single Shaft Shredder T Series

- Wiscon Crusher CS Series

- Wiscon Large Crusher CL Series

- Wiscon Large Double Shaft Shredder DL Series

- Wiscon Small Single Shaft Shredder P Series

- Kitech Compacting Pelletizing System - KCP

- Kitech Rigid Flakes Pelletizing System - KSP

- Wiscon Shredder-Crusher Combined CT Series

- Wiscon Confidential information destruction and crushing system

- Wiscon PP/PE Daily Miscellaneous Material Washing Line

- Wiscon PET Bottle Recycling System

contact us with

any

questions

Contact Us

Anytime

24/7 Service & Support

Huge Range Of Machinery Available

18 Months Warranty With Everything Sold

All Our Staff Are Service Technicians